With a team of metallurgists, research scientist and engineers we provide expertise in the following areas:

Package Manufacturing Consulting

Metallurgical Engineering, Materials Evaluation and Failure Analysis

Microscopy and Scanning Electron Microscope (SEM) Analysis

Chemical Analysis of ferrous, non-ferrous, alloys, powders, compounds and liquids

- Metal package product management

- New product development from concept to commercialization

- Quality improvement

- Materials specification evaluation

- Supplier audit

- Alternative materials selection and cost reduction

- Coatings and compounds evaluations

- CAD design and R&D

- Prototype development

- Design improvements

- Engineering mechanics including finite element analysis and stress analysis

- Six sigma methodology in product development and process improvement

- Lean manufacturing including value engineering, waste and cost reduction analysis

- Package performance test procedure development

- Product to Package compatibility testing

- Simulated shipping, distribution and handling tests

- Package shelf life evaluation

- Package graphics evaluation and improvements

- Label design and artwork

- Label specification development

Package Manufacturing Consulting:

- Project management in:

- Equipment Selection and specification development

- Equipment Installation and Operation

- Cost reduction and value analysis

- Alternate packaging equipment and system analysis

Metallurgical Engineering, Materials Evaluation and Failure Analysis:

Materials evaluation including:

- Aluminum wrought and casting alloys

- Low carbon steel and high alloy tool steel

- Stainless steel alloys

- Copper based alloys

- Aluminum bronze and zinc alloys

- Cast iron

- Powdered metals and carbides

- On and off site failure analysis including determining failure mode and determination of possible cause of failure

- Foundry technology consulting including sand casting, continuous casting, lost-foam technology and extrusion metallurgy of ferrous and non-ferrous alloys.

- Metallography and microstructure evaluation of ferrous and non-ferrous alloys

- Grain size measurement and evaluation

- Particle count and porosity measurements

- Heat treatment evaluation of metallic parts and structures including, decarburization, carburization anaylsis and identification of various metallurgical phases

At Ellia Engineering and Consulting we provide wide varieties of metallurgical, mechanical and chemical analysis on various raw, semi-processed and finished materials. These independent tests can help our clients to determine whether the material meets manufacturing standards and specifications.

Based on our client's needs and applications, we can recommend materials that have superior performance and are more cost effective than the materials our clients currently use.

The following is a list of metallurgical tests that we perform at our lab:

- Uni-axial tensile stress test

- Stress and stain evaluation

- Compression test

- Rockwell hardness test

- Micro-hardness test including Vickers and Knoop hardness tests

- Portable hardness test

- Fatigue test

- Torque test

- Impact test

- Dimensional analysis

- Heat treat furnace troubleshooting and evaluation

- Case hardening depth measurements of steel

Microscopy and Scanning Electron Microscope (SEM) Analysis:

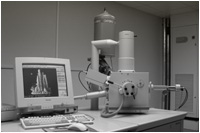

One of our key expertise in materials evaluation and failure analysis is use of various microscopy techniques. Our microscopy lab is equipped with:

- State-of-the-art optical stereo microscopes supplemented with digital imaging

- Research grade metallurgical microscopes (matallographs)

- Scanning electron microscopes (SEM) equipped with light element energy dispersive X-ray spectrometer (EDS); digital image analyzer and an ultra light load Knoop and Vickers micro-hardness tester

Chemical Analysis of ferrous, non-ferrous, alloys, powders, compounds and liquids including:

- Energy Dispersive X-ray spectroscopy (EDX) analysis

- X-ray fluorescent (XRF) analysis

- Fourier Transform Infrared Spectroscopy (FTIR)

- Spectrographic chemical and compositional analysis

- Stress corrosion evaluation and hydrogen embrillment investigation

- Intergranular and Transgranular corrosion analysis

- Simulated environmental (heat and humidity) tests

Our Ph.D. metallurgists and professional engineers can assist our clients in providing unbiased expert witnessing in a court of law. Our staff is experienced in working with legal counsels in presenting facts and data based on laboratory test results. We can represent both plaintiffs and defendants in a variety of liability cases.